Feb 28, 2025

Doctoral student receives patent for ammonia engine

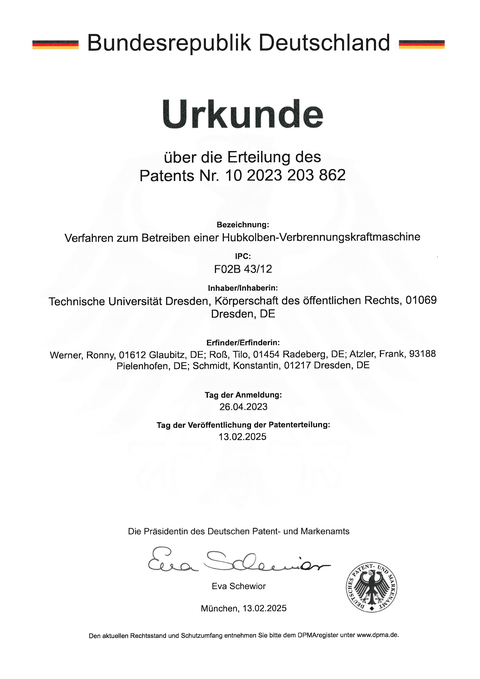

On February 13, 2025, doctoral student Mr. Konstantin Schmidt (Project H4: "H2 and H2-based fuels in internal combustion engine applications") together with Dr. Ronny Werner, Dr. Tilo Roß and Prof. Frank Atzler (Chair of Combustion Engines and Drive Technology at TU Dresden) received the patent certificate for the registration of the jointly developed patent entitled: "Method for operating a reciprocating engine" (DE 10 2023 203 862 B4).

Ammonia as an energy source

Alongside hydrogen, ammonia as an energy carrier is a promising candidate for the decarbonization of industry and the transport sector. The high volumetric energy density and easier handling compared to hydrogen make ammonia particularly attractive for mobile applications and transportation over long distances.

Challenges of ammonia combustion

The use of ammonia as a fuel in combustion engines, specifically internal combustion engines, is possible, but is associated with various challenges. For example, the low flame speed and the high ignition delay limit the achievable speed of the combustion engine and thus also its capabilities.

Project schedule

In 2022, a research project on the use of ammonia in small, high-speed engines was launched as part of Mr. Konstantin Schmidt's diploma thesis. Initial investigations were carried out using 3D CFD simulations to analyze the ignition and combustion behavior under engine-like conditions and to define parameters for subsequent experiments. In the further development of the project, an existing test bench at the Chair of Internal Combustion Engines and Drive Systems at TU Dresden, a constant volume chamber, was upgraded for ammonia operation. The newly developed combustion process was then successfully demonstrated for various operating points.

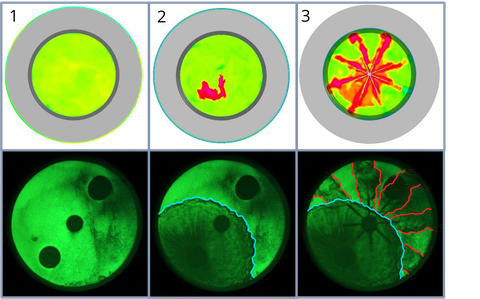

The combustion process: FSJI - Flame Supported Jet Ignition

To improve the ignition properties of the ammonia, a small amount of hydrogen is required, which is obtained directly onboard by catalytic splitting of the ammonia. The overall efficiency is hardly affected by the use of exhaust gas heat. The hydrogen obtained in this way is mixed with air in the cylinder (1) and spark-ignited as in a classic petrol engine, forming a flame front around the spark plug (2). Behind the flame front is the localized combustion area into which ammonia is directly injected, similar to the diesel process (3). It ignites due to the high temperatures. The name of the process is derived from the fact that the ignition of the ammonia jets is supported by the hydrogen pre-combustion.

FSJI process, simulation results above, test bench images below (hydrogen pre-combustion area in blue, burning ammonia jets in red)

Next steps

In the future, the experiments are to be extended to an optical single-cylinder test engine in order to test the functionality under real engine conditions. The measurement data obtained will be used to further calibrate the simulation models and thus flow directly into sub-project H4.