Reinforcements made of rCF

Table of contents

Project data

|

Titel | Title |

Report in the annual report 2023

Old becomes new

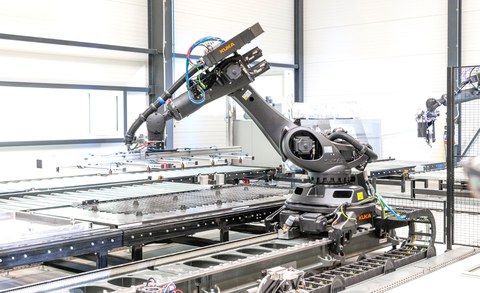

Direct yarn placement for the production of grids

The joint project, funded by the Federal Ministry of Education and Research, uses the knowledge gained in the WIRreFa basic projects as a starting point. The project aims to develop and implement the previously created process chain. Various technologies, including pultrusion, warp knitting technology, and direct yarn placement are available for producing reinforcements in form of rebars and grids. The partners’ reinforcements undergo examination, evaluation, and development, using components and semi-finished products for carbon-reinforced concrete as an example. Investigating materials made from recycled carbon fibers (rCF) yields characteristic values for updating the numerical model.

Within the project, we started with an investigation of various carbon fiber rebars and their surface profiling with the aim of finding the optimal geometric profiling for carbon rebars made from rCF. The profiling has to be application-oriented, suitable for the material, and appropriate for production. To assess the performance of rebars and grids made of rCF, reference tests will be conducted using carbon rebars and grids made of virgin fibers. Furthermore, investigations are planned to analyze fiber orientation, length, and volume content. The project also includes the use of rCF rebar mats.

Additionally, the construction sector should consider non-metallic connecting elements. The objective is to create a high-performance fastener that can connects slim carbon-reinforced concrete elements and minimizes thermal bridges. The study will evaluate the performance and suitability of current fasteners. The insights gained will serve as a foundation for developing fasteners made from recycled carbon fibers.

In the later stages of the project, there are plans to produce and test sample components made of carbon-reinforced concrete.