C3-V2.3-I-a: High temperature exposure

Table of contents

Project data

| Titel | Title TP C3-V2.3-I-a: Materialverhalten von Carbonbeton unter Hochtemperaturbeanspruchung im Verbundvorhaben C3-V2.3: Brandverhalten von Carbonbeton | TP C3-V2.3-I-a: Material behaviour of carbon reinforced concrete exposed to high temperatures as part of the joint research project C3-V2.3: Fire behavior of carbon reinforced concrete Förderer | Funding Bundesministerium für Bildung und Forschung (BMBF); Projektträger: FZ Jülich GmbH / C3 – Carbon Concrete Composite Zeitraum | Period 05.2017 – 09.2020 Leiter Teilvorhaben | Subproject manager Prof. Dr.-Ing. Dr.-Ing. E.h. Manfred Curbach Bearbeiter*in | Contributors Dipl.-Ing. Karoline Holz, Dr.-Ing. Daniel Ehlig, Dipl.-Ing. Olga Diring, Dipl.-Ing. Elisabeth Schütze, Dipl.-Ing. Ronghua Xu Projektpartner | Project Partners 4 Partner, davon 1 aus der Forschung und 3 Firmen |

Report in the year book 2020

CARBON REINFORCED CONCRETE UNDER HIGH TEMPERATURE

Experimental setup for tensile tests under high temperature

The high-temperature tests carried out on carbon concrete structures showed that at higher temperatures, concrete failure often occurred due to splitting in the layer of the fabric. For example, the concrete failure can be observed in the tensile tests of the material combination of textile reinforcement solidian Q95 and highstrength concrete C3-HF2-145-5 from a temperature of 400 °C. The tensile strength at 400 °C is approx. 2000 MPa, which corresponds to almost 70% of the reference values at 20 °C and is therefore very satisfactory. To optimize the concrete mixes, a plastic-modified repair mortar StoCrete TG203 of fire resistance class F90, which is already available on the market, was selected and tested in tensile and bond tests with textiles soaked with epoxy resin or acrylate. Compared to normal concrete, the mortar has polypropylene fibres (PP fibres), which decompose without leaving any residue at high temperatures and thus create a porous system. This enables a non-destructive diffusion of water vapour and consequently concrete spalling can be prevented. However, the addition of PP fibres harms processability and also reduces compressive strength. The results showed that concrete spalling can be prevented with the help of the mortar, but not the splitting of the test specimens along the plane of the fabric’s layer.

The temperature-dependent load bearing behaviour of carbon textile reinforced concrete has been known for a long time. Numerous tensile and bond tests on carbon concrete show a decrease in both tensile and bond strength over temperature. However, there is only a little knowledge about the use of carbon fibre rebar as reinforcement. Stationary tensile tests were carried out to gain more knowledge about the mechanical properties of carbon fibre rebar. The accompanying pull-out tests to investigate the bond strength were carried out by MFPA Leipzig GmbH. The so-called “Carbon4ReBar” carbon fibre rebar with a core diameter of 8.5 mm from ThyssenKrupp was used as reinforcement. The concrete used for the tests was a high-strength concrete, which was developed in the V2.3 project “Fire behaviour of carbon concrete”. The specimens were tested with a concrete age of more than 56 days to avoid possible concrete spalling during the test. An approximately linear relationship between tensile strength and temperature is formed from the results of the tests. At a temperature of 300 °C, only approximately 45% of the initial value is reached.

Report in the year book 2019

FIRE PROTECTION MEASURES TO INCREASE FIRE RESISTANCE

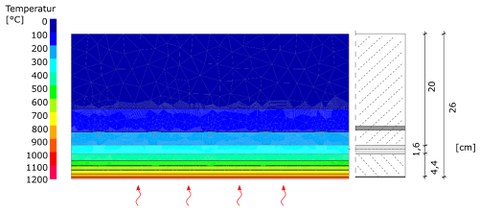

Temperature calculation for steel reinfored concrete beam with a strengthening layer of 16 mm with fi re protection coating Sika ® Unitherm® Concrete S

In the project C3 – Carbon Concrete Composite, the material behaviour of carbon concrete under high temperature and the fire resistance of carbon reinforced concrete will be researched. Based on the previous experimental results of material characteristics of carbon concrete, the tensile strength and bond strength will decrease with an increase of temperature. The reason is that the impregnation of carbon fibres is softened after the glass transition temperature is reached. Above the temperature of 600 °C, the carbon fibre will completely lose its strength. So it is crucial to take fire protection measures to increase the fire resistance of building components.

Within the frame of the project, three different types of fire protection were researched, to compare their ability to fire resistance. A carbon textile reinforced concrete beam with a strengthening layer of 16 mm was used for the experiments. During the first experiment, the beam was heated for 90 min, according to the temperature-time curve without extra fire protection measurements. The temperature in the strengthening layer reached 800 °C, which meant that the strengthening layer had lost his reinforcing effect. In the next steps, the experiments were carried out respectively with three different fire protection coatings.

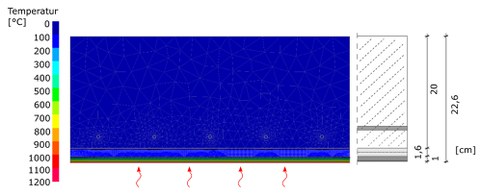

Temperature calculation for steel reinforced concrete beam with a strengthening layer of 16 mm with fi re protection plaster Dossolan-Thermique

The first coating Sika® Unitherm® Concrete S showed, that the temperature in the strengthening layer reached 300 to 400 °C. This coating is extremely thin, and it will foam in case of fire. The second coating, Dossolan-Thermique, was a fire protection plaster. It reduced the temperature in the strengthening layer to 100 ... 200 °C after heated for 90 minutes. Thus, the carbon fibres in the strengthening layer could contribute to the reinforcing effect. The last fire protection measure was a fire-resistant plate, which made it possible, that the temperature in the strengthening layer stayed between 200 and 300 °C. According to the achieved results, fire protection coatings are suitable for fire prevention with low requirements. If high requirements of fire prevention are needed, then the fire protection plaster or a fire-resistant plate must be applied.

Report in the year book 2018

CARBON REINFORECED CONCRETE UNDER HIGH TEMPERATURE – TENSILE TESTS

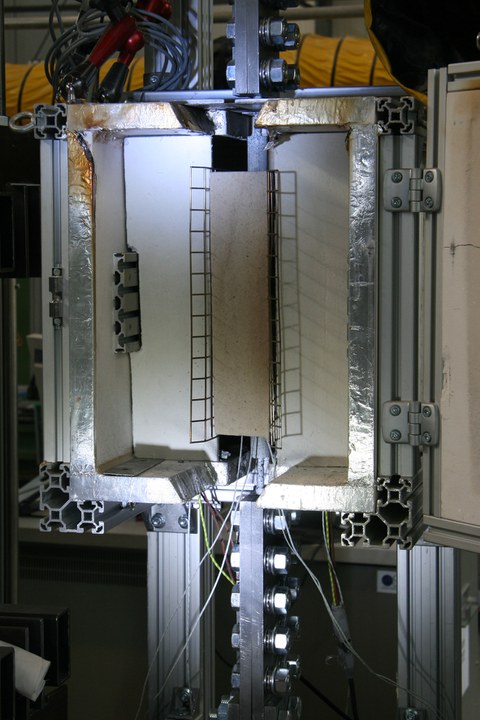

Heating chamber and tensile specimen in the heating chamber with measurement technology

In order to be able to describe the material behaviour under high temperature, tensile tests were carried out. As part of the project, both tensile and bond tests were executed at high temperatures. Initially, it was planned to prepare a test setup for the fibre strand, as it is common with epoxy resin impregnated fibres at room temperature. However, this was not possible, because opposing infrared heaters would heat each other during the test. Therefore, a composite test specimen was chosen for the tensile tests. During testing of the specimen, it was possible to observe effects of the interaction between reinforcement and concrete under high temperature.

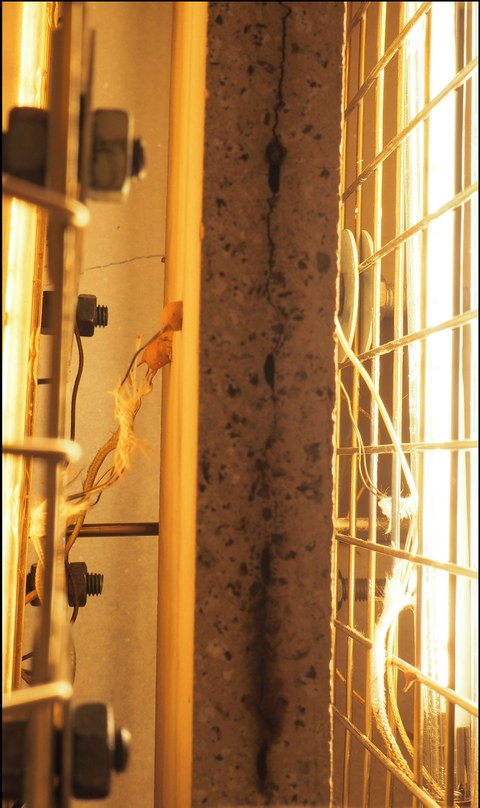

Splitting in the textile plane during heating

Two material combinations were examined with regard to their behaviour under high temperature. On the one hand a textile impregnated with epoxy resin, on the other hand a textile with an acrylate-based impregnation. The two materials are intended to represent the two applications of new construction elements and strengthening. To investigate the pure material behaviour under high temperature. Tensile tests were carried out at defined temperatures and yielded in temperature specific stress-strain curves. In order to check the transferability of the results obtained from the test under defined temperature conditions, tests were carried out at a defined load level, while the temperature was increased continuously. This represents the real case in the construction element, even in case of fire, the construction element is exposed to stress and the temperature rises. As a result of these investigations, a temperature-reduction curve was obtained. It turned out that there are no differences in the results between these two experiments.

A high-strength concrete matrix was used in the tests of the material combination for new construction elements. Even during heating, the temperature effect caused the composite material to split in plane of the reinforcement. This shows that additional measures have to be taken to make this concrete matrix suitable for use under high temperature conditions. Also with the material for the strengthening, spalling phenomena occurred during the tests without prior generation of a crack pattern due to the low permeability.

Report in the year book 2017

WHAT HAPPENS WHEN IT BURNS?

Possible bond test

An investigation of the material behaviour of carbon reinforced concrete exposed to high temperatures and fire is required to open up a larger scope of application in building industry. The determination of the parameters for a concept of the structural fire design for carbon reinforced concrete is another basis for the marketability of the composite.

The basic material requirements which are related to fire safety are set out in various national and European regulations. These requirements were compiled at the beginning of the project.

The necessary tests were derived from these. The tests for determining the fire classes and fire resistance classification are carried out at MFPA Leipzig GmbH as part of the project. Another focus is the experimental characterization of carbon reinforced concrete with textile reinforcement exposed to high temperature. For this purpose suitable experimental setups are to be developed for the several textile reinforcements which have different properties. The investigations include the tensile and the bond behaviour when the sample is exposed to high temperatures. Based on the test recommendations of the basic project C3-B3, the high-temperature tests are adjusted. There is still room for improvement, especially in the case of textile reinforcement with an impregnation based on epoxy resin. For these materials, it is possible to test the tensile strength on a single fibre strand or on the composite. The specimen’s geometry had to be changed compared to that for specimens made with textile reinforcement with styrene-butadiene impregnation (SBR) so the test setup has to be adapted too. Another reason for the modification of the test setup is that controlling the temperature during a test of a single fibre strand is a challenge because the two-sided spotlights influence each other. The C3-B3 bond strength tests can be recommended for high temperatures also only for SBR impregnated textiles. For textiles impregnated with epoxy resin, a suitable experimental set-up must be developed first.

Based on the experimentally determined material characteristics at elevated temperatures, in the next step, coefficients can be determined which take into account the drop in strength with rising temperatures. These coefficients can be integrated into the structural fire design. The final step of these investigations is to transfer the safety concept from Eurocode 2 to the determined material characteristic.